You have got a lot on your plate when it comes to launching your new product. Finding the right vendor to mold your plastics is just one to-do on a very long list. Following is some advice to help with your search.

What is the difference between Injection Molding and Blow Molding?

Many service providers specialize in one or the other of these molding techniques. Knowing which type of molding your product will require will help you narrow down your list of vendors.

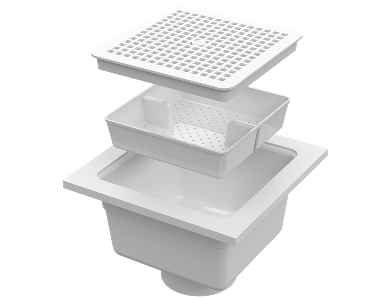

The name gives you a hint as to the process. Injection molding refers to a process where resin is heated and then injected at very high pressure into a mold. What you end up with is a solid, rigid product. The bumper of your car most likely used injection molding, as did the handle of your favorite screwdriver.

Blow molding is when a heated plastic tube is filled with air (much like blowing up a balloon), and then the mold is clamped around it. The tube continues to fill with air until it fills the mold and becomes the desired shape. What you end up with is a hollow part. Blow molding is the process used when making most plastic bottles.

Acorn-Gencon® Plastics provides complete injection-molded product solutions from concept to completion. Not only can we do the manufacturing for you right here in the United States, but we can help with the engineering and packaging as well.

How important is the mold?

With injection molding, the mold itself is critical. Your vendor is going to need to know what classification you want the mold built to. There are five different classifications, but all you pretty much need to know is how many products you want to produce. As you can imagine, the wear and tear on your mold is going to increase if you are making 1,000,000 products a year vs. just 500.

Why wouldn’t you just choose the highest class mold made from stainless steel to get the best mold possible? Well, that stainless steel mold is a lot more expensive to build. It is meant to handle 1,000,000 shots or more a year. If your expectations are closer to 10,000 parts produced, you should save yourself some money and go with a lower classification.

Are all plastics the same?

No, all plastics are not the same. In fact, you will have to decide what type of resin is going to be used to make your product. Luckily, you do not have to be an expert on resins, SPI standards on finishes, and shrink rates to make this decision.

Choose a service provider that can advise you on which plastic is right for you. You will need to tell them how your product will be used. They should be able to tell you if you need a food grade, medical grade, or another type of plastic. They will also want to know what temperatures and elements your product will be exposed to. Is your product a water bottle that will be used by mountain climbers in the Himalayas? Is it a replacement human heart valve? Or, is it a cover to protect an iPhone when deep sea diving?

Do you have the answers to these questions? Then you are ready to start your search for the best service provider who can meet your needs.

Are you interested in finding more about Acorn-Gencon® Plastics and the services we provide? Give us a call at our Chino, CA headquarters—909-591-8461. You can also request a quote here.